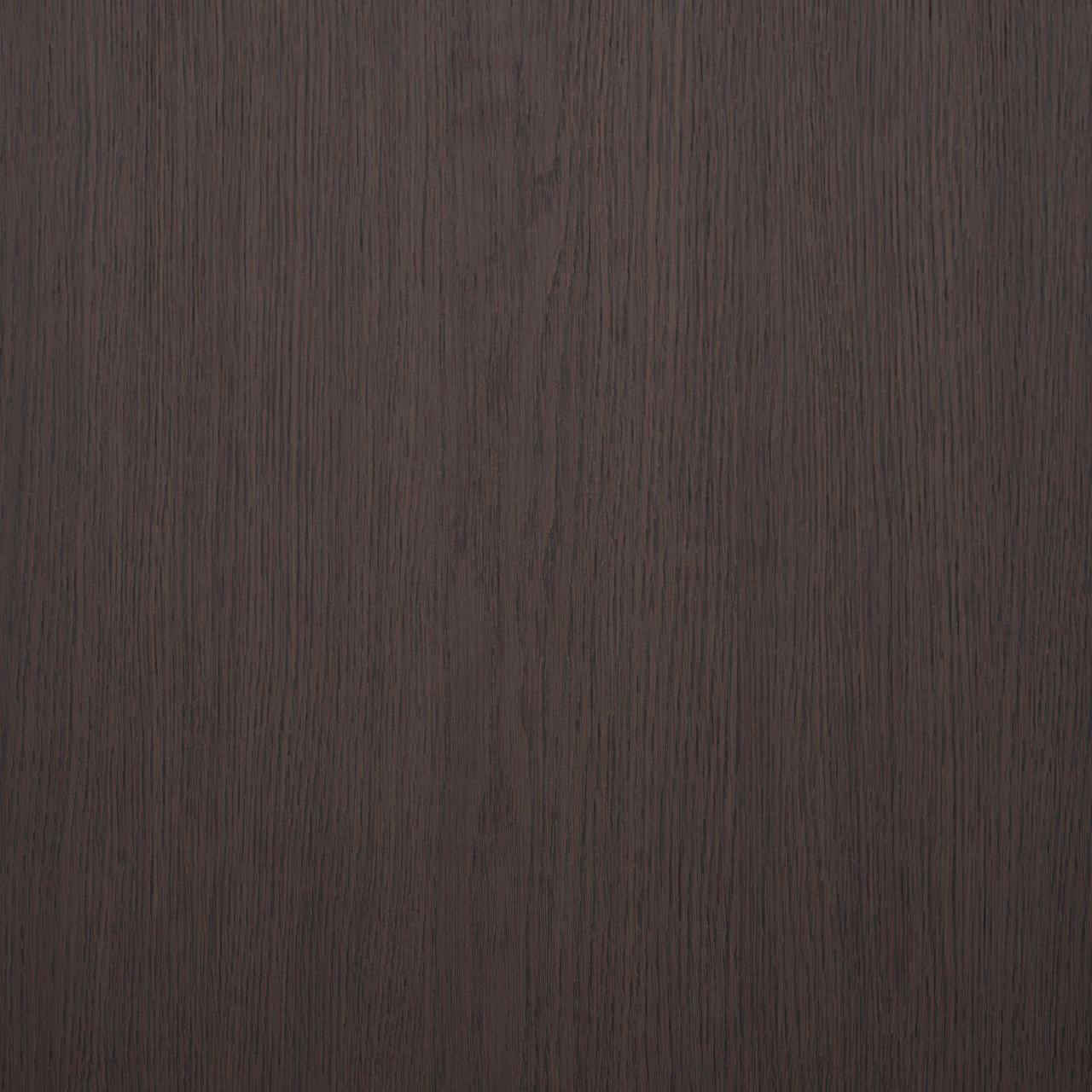

Dura Oak

Dura Oak

Dura Oak combines the unique look and feel of original oak with the unbeatable qualities of a HPL: more scratch resistant, colourfast and easy to keep clean.

Bonded durably on two sides of Latvian Birch, Dura Oak’s matt finish delivers a luxurious appearance and has a unique pattern just like original oak. The natural appearance of Master Oak is enhanced by the different types of pores and depth variations throughout the panel.

Scratch-resistant: three times more scratch resistant than Oak veneer.

Colourfast: a timeless look and colours that stay beautiful.

Stain-resistant: easy to clean and maintain.

Matching ABS edging is available in both long and end grain to replicate the look of solid oak timber.

Dimensions:

3020 × 1250 ×19mm Face 2 sides

3050×1200× 0.7mm Laminate Only

Key Features

Ultra realistic oak texture

No Repetitiveness within the sheet

Anti-bacterial & Food Safe

Scratch-resistant: three times more scratch resistant than Oak veneer.

Colourfast: a timeless look and colours that stay beautiful.

Stain-resistant: easy to clean and maintain

Matching ABS edging is available in both long and end grain to replicate the look of solid oak timber

Application

Ideal for Kitchen and bathroom cabinetry (vertical surfaces). Residential, commercial, office, retail and hospitality fitouts.

Wall linings

IMPORTANT NOTES

• The protective film must be removed slowly and carefully to ensure the best possible finish and to minimise any potential residue from the film layer.

• If cleaning is required, use a citrus-based or similar gentle cleaner.

• Due to the clearance nature of this stock and the 50% discounted pricing, returns will not be accepted. All sales are final.

• If customers intend to use the panels for vertical applications, recommend they test the adhesion of cleaning products on a small area first.

• Panels should be stored in dry, well-ventilated areas before installation to avoid moisture-related issues.

• Remind customers that all cut edges must always be sealed — no exceptions — particularly for applications in wet or humid environments. This is critical to maintaining the panel’s performance and longevity”